|

PBI

GOLD's Contribution

PBI

(Polybenzimidazole), was originally

developed for the NASA Apollo space program, is an extraordinary

organic fiber that does not burn in air. The leader of this revolution

in fire fighting gear is a fabric – PBI

GOLD®

developed by Celanese Acetate LLC. It is a blend of 40% PBI and

60% Aramid woven in a ripstop construction and therefore combines

the superior thermal, chemical and comfort qualities of PBI, with

the high strength quality of aramid, the fiber is made for bulletproof

vests. PBI GOLD®

provides outstanding thermal performance, and excellent resistance

to solvents, fuels, caustics, and strong acids. But, as tough as

it is, PBI GOLD®

is soft and supple, for the comfort and need of mobility firefighters.

It cleans easily so it does not need special treatment. PBI

(Polybenzimidazole), was originally

developed for the NASA Apollo space program, is an extraordinary

organic fiber that does not burn in air. The leader of this revolution

in fire fighting gear is a fabric – PBI

GOLD®

developed by Celanese Acetate LLC. It is a blend of 40% PBI and

60% Aramid woven in a ripstop construction and therefore combines

the superior thermal, chemical and comfort qualities of PBI, with

the high strength quality of aramid, the fiber is made for bulletproof

vests. PBI GOLD®

provides outstanding thermal performance, and excellent resistance

to solvents, fuels, caustics, and strong acids. But, as tough as

it is, PBI GOLD®

is soft and supple, for the comfort and need of mobility firefighters.

It cleans easily so it does not need special treatment.

Field

Proven in Project FIRES, NFPA and EN469 standard

Turnout

coats made with PBI GOLD®

have proven themselves through extensive field-testing in 14 cities,

under the guidance of the International Association of Firefighters

and the International Association of Fire Chiefs. As a result, PBI

GOLD®

is now specified as the preferred shell fabric for ensembles meeting

with Project FIRES criteria. Turnout

coats made with PBI GOLD®

have proven themselves through extensive field-testing in 14 cities,

under the guidance of the International Association of Firefighters

and the International Association of Fire Chiefs. As a result, PBI

GOLD®

is now specified as the preferred shell fabric for ensembles meeting

with Project FIRES criteria.

Moreover, it far exceeds NFPA and EN469 requirements, remaining

to be flexible and strong, even with severe thermal exposure. It

is a combination of benefits that no other fabric can match. Since

1983, PBI GOLD®

has been widely recognized as the premium product in outer shell

and hood protection.

PBI GOLD's Privilege

The test results shown below are further evidence

of the toughness and superior thermal protection offered by PBI

GOLD®

, the outshell fabric used by Vulcan®.

PBI GOLD®

exceeds NFPA and EN469 requirements. In addition, it outperforms

competitive fabrics in many tests. In the results reported here,

PBI GOLD®

is compared with a traditional aramid. Both fabrics weigh 7.5 oz/yd2.

Resists

Flame

In

U.S. Army laboratory tests ( AFML TR-73-28), flight-suit prototypes

were evaluated in a pit containing burning JP-4 jet fuel. These

tests subjected an instrumented mannequin to a 3-second flame exposure.

Sensors measured temperature rise and predicted the extent of skin

damage a human wearer would sustain in an exposure equivalent to

test conditions. The mannequin wearing a flight suit made with PBI

GOLD®

sustained only 2% skin damage as compared to 20% for flight suit

made with aramid. The superior flame resistance of PBI

GOLD®

is also reflected in the following tests: In

U.S. Army laboratory tests ( AFML TR-73-28), flight-suit prototypes

were evaluated in a pit containing burning JP-4 jet fuel. These

tests subjected an instrumented mannequin to a 3-second flame exposure.

Sensors measured temperature rise and predicted the extent of skin

damage a human wearer would sustain in an exposure equivalent to

test conditions. The mannequin wearing a flight suit made with PBI

GOLD®

sustained only 2% skin damage as compared to 20% for flight suit

made with aramid. The superior flame resistance of PBI

GOLD®

is also reflected in the following tests:

-

FSTM

191-5903-Expose fabric samples vertically to a 1600°F flame

for 12 sec.

-

Similar

but more severe test, FSTM 191-5905, exposes the samples to

a 1750°F flame for two 12-second exposure.

Superior

Thermal Performance

PBI

GOLD®

has superior thermal performance as indicated by the following test

results: PBI

GOLD®

has superior thermal performance as indicated by the following test

results:

-

A

fabric’s limiting oxygen index (ASTMD-2863) indicates

the level of oxygen required to sustain continuous burning and

consume a 5-cm fabric strip in 3 minutes. PBI

GOLD®

with higher limiting oxygen values are more difficult to ignite.

-

The

contact heat ignition test measures the number of seconds to

ignite a fabric that is in contact with 860°C steel at a

1-psi load.

Strong

and Tough

These

test results below show the strength and toughness of PBI

GOLD® (In the

tear and tensile tests, samples were cut to test yarns along with

the warp X filling of the fabrics.) These

test results below show the strength and toughness of PBI

GOLD® (In the

tear and tensile tests, samples were cut to test yarns along with

the warp X filling of the fabrics.)

-

Burst

Strength test (ASTMD-3787) indicates the fabric’s resistance

to puncturing when a force is applied at right angles to the

fabric surface.

-

Tear Strength test (ASTMD-1424) indicates the resistance to

accidental tearing.

-

Tensile Strength test (ASTMD-1682) shows the force required

to rupture the fabric.

Resists Chemicals

The tests reported below

measured strength loss of the PBI

GOLD® after 10-hour exposures to

a variety of common chemicals. All of the chemicals were at 21°C.

After exposure, the tensile strength test (ASTMD-1682) was used

to measure strength loss and for:

1.

0-15% degradation were rated as “None”

2. 16-30% degradation was rated as “Slight”

3. 31-45% degradation was rated as “Moderate”

| Chemical

|

Concentration % |

Strength

Loss |

| Alkali |

| Sodium

Hydroxide |

40 |

None |

| Ammonium

Hydroxide |

30 |

None |

| Acids |

| Hydrochloric |

10 |

Slight |

| Nitric

|

10 |

Slight |

| Phosphoric |

60 |

Moderate |

| Sulfuric

|

60 |

Moderate |

| Sulfuric

(Battery Acid) |

40 |

Moderate |

| Solvents |

| Benzene

|

100 |

None |

| Perchloroethylene |

100 |

None |

| Acetone

|

100 |

None |

| Hydrogen

Peroxide |

3 |

None |

| Fuels |

| Gasoline

|

100 |

None |

| Kerosene

|

100 |

None |

| Diesel

Fuel |

100 |

None |

|

Turnout Gear with Excellent Comfort

PBI

GOLD®

has soft, natural aesthetics and excellent

comfort. Compared with other high-performance fibers, PBI fiber’s

low modulus and its elongated cross section are like that of cotton.

Both of these factors are contributed by the softness and flexibility

of fabrics made with PBI. In addition, PBI (with a moisture regain

of 15%) is 50% more absorbent than cotton. Gillette Research Institute

independently compared the comfort of PBI garments with cotton garments

and judged PBI comparable to cotton in comfort. With a good choice

of moisture and thermal barriers, Vulcan offers you excellent comfort.

Offers Excellent Electrostatic

Dissipation

PBI’s chemical structure and high moisture

regain contribute to excellent static dissipation, as shown in Table

Below. PBI GOLD®

surface resistivity is 1000 times lower than aramids. In

addition, PBI shows no static cling to nylon fabric at humidities

as low as 25 % RH.

Ambient

Conditions |

Surface Resistivity (ohms/cm2) |

Static

Cling (AATCC-115-1977) |

68F,

25%RH |

16x1010 |

0 |

68F,

45%RH |

5x1010 |

0 |

68F,

60%RH |

2x1010 |

0 |

68F, 65%RH |

1x1010 |

0 |

|

About

the structure of

Vulcan®

fire-fighter suits, it comes with 3 and 4 layers :

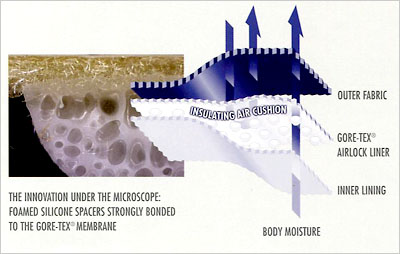

The

above picture shows the structure of the Gore-tex®

airlock

system with both moisture barrier and heat barrier functions.

Outer

layer: PBI GOLD®

fabric

Middle layer: GORE-TEX®

waterproof breathable layer

Inner layer: Flame retardant interlining layer

is a registered trademark of Celanese Acetate LLC.

is a registered trademark of Celanese Acetate LLC.

Kevlar®

and Nomex®

are trademarks of E. I. au Pont oc Nemours & Co., Inc.

is a registered trademark of Millennium Advance Technology.

is a registered trademark of Millennium Advance Technology.

Crosstech®,

Gore-tex®,

Fireblocker®

and Airlock®

are the registered trademarks of W.L. Gore & Associates Inc.

Vulcan

utilizing PBI GOLD®

as the outershell with different kinds of high performance moisture

and thermal barriers such as Crosstech®,

Fireblocker®,

Airlock®

and others, is engineered to meet all the tough demands of a firefighter’s

job.

|